REDUCING OUR ENERGY CONSUMPTION

Sourcing renewable energy is critical to VF’s environmental sustainability strategy and central to reducing our greenhouse gas (GHG) emissions across our global value chain. To achieve our SBTi-approved climate targets, we’ve made renewable energy sourcing and energy efficient buildings central components of our sustainability strategy.

Achieving 100% Renewable Energy

In 2016, VF joined RE100, a global corporate renewable electricity initiative bringing together hundreds of large and ambitious businesses committed to 100% renewable electricity.

As a RE100 member, VF has committed to utilizing 100% renewable energy across our owned-or-leased facilities by the end of FY2026 through on-site renewable energy projects and off-site renewable energy investments, including purchase of renewable energy credits (RECs).1

View ProgressADVANCING RENEWABLE ENERGY

“VF’s renewable energy strategy is a commitment to source clean energy across our business that minimizes environmental and social impacts for neighboring communities.”

– Jeannie Renne-Malone

Vice President, Global Sustainability

VF’s State-of-the-art Distribution Center

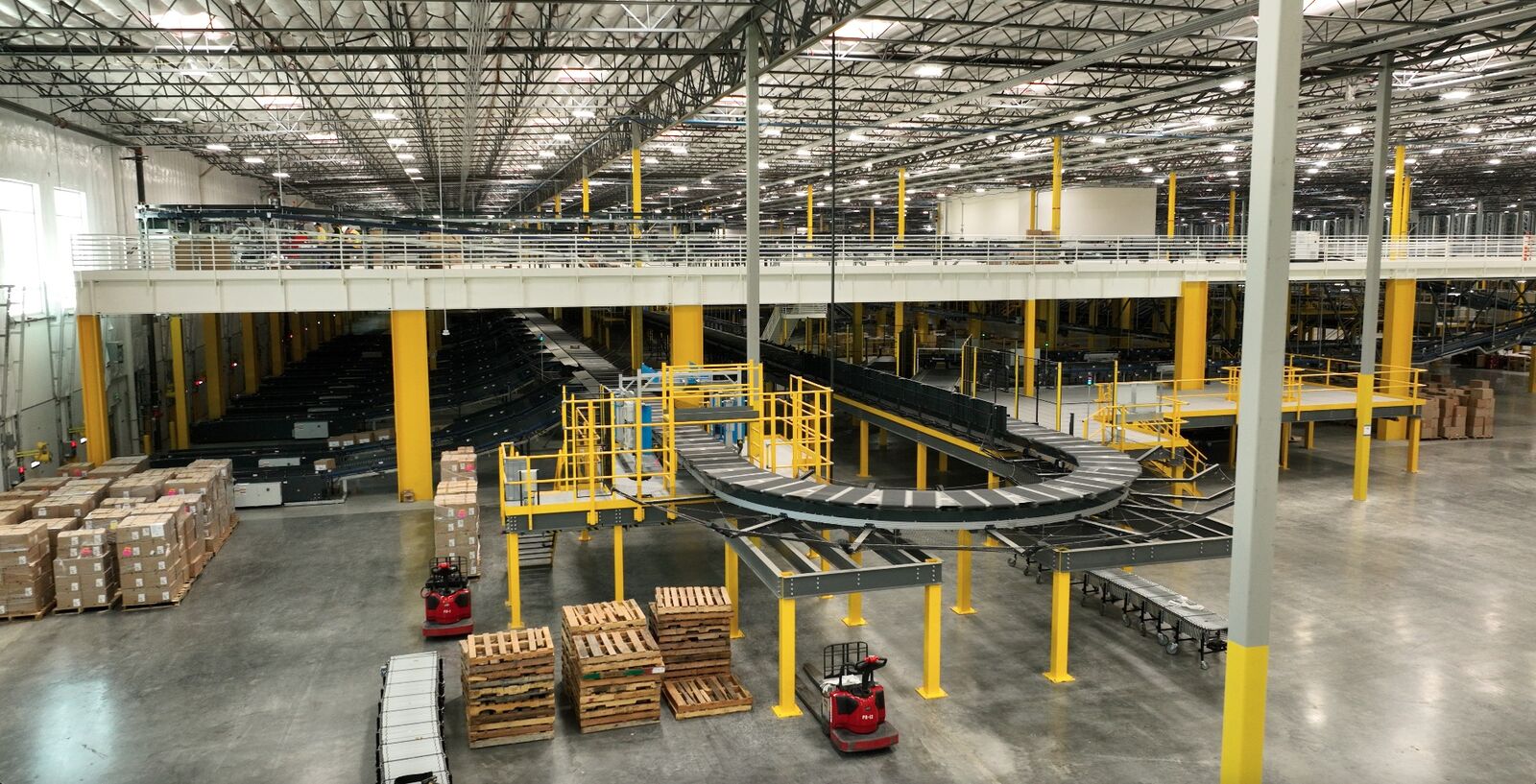

In 2023, VF opened a new 1.2 million square foot distribution center in Ontario, CA. This facility is the largest and most efficient within VF’s global network of 46 distribution centers, initially servicing Vans® and The North Face® brands, with the capability to process products from additional VF brands in the future.

The new distribution center was designed and constructed to support VF’s sustainability commitments, with features that help reduce the impact on the environment, including an estimated 56% in annual energy cost savings through energy efficient lighting, controls and submetering, a total of 48% recycled content in building materials, diversion of 98% of construction waste from the landfill, and designing for daylight and views in the regularly occupied areas of the building. The building design and construction has achieved LEED Gold certification. LEED, or Leadership in Energy and Environmental Design, was created by the U.S. Green Building Council (USGBC) and is the world’s most widely used green building rating system. In March 2024, the building achieved WELL Gold certification, a performance-based standard that focuses on enhancing health and wellness, managed and administered by the International WELL Building Institute (IWBI).

GREEN BUILDINGS

Adhering to Green Building Standards helps us save on energy costs and reduce facility-related GHG emissions, which is critical to meeting our SBTs. Our owned-or leased facilities accounted for over 90% of our location-based Scope 1 and 2 emissions in 2021. As of FY2024, 17 VF buildings are LEED certified by the U.S. Green Building Council or meet the BREEAM requirements for Good or Very Good rated buildings.

VF’S LEED Platinum Headquarters

Our Denver headquarters is certified to LEED Platinum, the highest rating level from the U.S. Green Building Council. The building is also VF’s first to be wellness certified, earning Fitwel 1-Star recognition and offers employees a variety of wellness amenities, including a climbing wall, expansive outdoor space and an altitude training room.

In alignment with VF’s Green Building Standards, the building’s real-time energy monitoring, electric car charging stations and waste management system reduce the facility’s environmental footprint while aiming to improve associate health and well-being.

PROMOTING RENEWABLE ENERGY ADOPTION IN THE SUPPLY CHAIN

Most of the environmental impacts of our business, occur in our supply chain. That’s why we are collaborating with industry associations, supply chain partners and key stakeholders to measure our impact, share best practices and implement programs to drive meaningful change beyond our direct operations. To date, VF has trained 1,000+ supplier factory representatives on energy efficiency and resource management best practices and is expanding our supplier sustainability programs across several key sourcing countries.

ADVANCING SUPPLIER ENVIRONMENTAL SUSTAINABILITY

VF is working across the supply chain to improve environmental sustainability, increase energy efficiency and reduce GHG emissions. Through VF supported supplier sustainability programs, factories in Bangladesh, Vietnam and others have generated more than 593 million MJ (megajoule) per year in energy savings since 2018. Strategic partnerships enable us to scale our impact by engaging suppliers to pursue best practices in energy, water and chemical management. Together, we’re producing results where it counts: on factory floors. Recent and current partnerships include:

- Partnering with the IFC to develop a program for coal substitution at Tier 1 and Tier 2 factories and launching energy efficiency and productivity improvement programs for 13 suppliers in Bangladesh, Cambodia and Vietnam.

- Working with factories in countries, including Bangladesh, Cambodia, China and Vietnam, on various sustainability topics, including environmental management system (EMS) programs, climate action trainings and GHG reduction plans.

- Collaborating with the Apparel Impact Institute (Aii) Clean by Design program to support textile suppliers in China, Korea and Taiwan in a resource efficiency action plan.

ADDITIONAL RESOURCES

- Policies & Standards to access VF’s Green Building Standards

- Reporting & Data to access in-depth emissions and energy data

- Climate to learn more about VF’s science-based targets and climate advocacy.